ABOUT GBC

Company Profile

GBC Scientific Equipment Pty Ltd designs, manufactures and markets a range of analytical instruments: Absorption Spectrometer (AAS), Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES), UV-Visible Spectrophotometers (UV-Vis), Inductively Coupled Plasma Time-of-Flight Mass Spectrometer (ICP-oTOFMS), High Performance Liquid Chromatography (HPLC) and X-ray Diffractometer (XRD). GBC first commenced operations in 1978.

The company’s head office is based in Melbourne, Australia, with a manufacturing and training facility in Melbourne, Australia, and another in Penang, Malaysia. GBC is represented by one of the largest international distribution networks in over 100 countries. Over 40 years after inception, GBC is world renowned in the field elemental analysis field as a result of its quality products and services.

GBC customers benefit from our efficient and effective global organisation. Access to information, applications support and technical service is never more than a phone call or email away.

Our Mission Statement

- Delivering value to customers and providing outstanding levels of customer service and support.

- Continuous improvement and an open mind to new technologies.

- Making quality key in all we do.

Our Global Vision

Business Awards

- Australian Export Awards for Outstanding Export Achievement.

- The Age, Dun and Bradstreet, Victorian Business Award – Manufacturing Category.

- 100 Award (USA) – GBC OptiMass 8000 ICP-TOFMS.

- Australia’s Best Manufacturers Awards – Overall Achievement in Manufacturing Excellence.

- Australian Engineering Excellence Award – The Institute of Engineers Australia.

- Clunies Ross Award “For Excellence in the application of science and technology” received by Ron Grey Managing Director of GBC.

- Inducted into the Victorian Hall of Fame.

Process, Technology

and Facilities

The manufacturing plant incorporates:

Metal fabrication and machine shop

Metal fabrication and machine shop produces high quality sheet metal components and cabinetry as well as high precision machined components in metals, alloy, and engineering plastics.Paint shop and screen-printing facility

Paint shop and screen-printing facility for the metal pre-treatment, painting, and screen-printing on components and cabinetry employing spray paint booths, a chromate bath system, gas convection oven, and a quartz infra red oven.Electronic assembly and test

Electronic assembly and test production of printed circuit assemblies and wiring harnesses (looms). Printed circuit assemblies and looms are subject to stringent in process quality controls and testing.Optical coating and assembly

Coating of optical components and preparation of optical sub-assemblies ready for inclusion into the final instrument.Final assembly

Labour intensive, manual build processes are required for assembly of instruments and accessories by skilled operators.Final test and inspection

Complete testing and inspection of all manufactured and OEM products to meet all customer operating conditions.

Early History

The modern AAS instrument was pioneered by Sir Alan Walsh in the 1950s at the Commonwealth Scientific and Industrial Research Organization (CSIRO). In Melbourne, Australia, whilst gardening one weekend Walsh realized that measuring the absorption of light was more valuable than observing the emission.

GBC Scientific Equipment was founded in 1978 by Ron Grey, Ivan Bartlett and Peter Charlton.

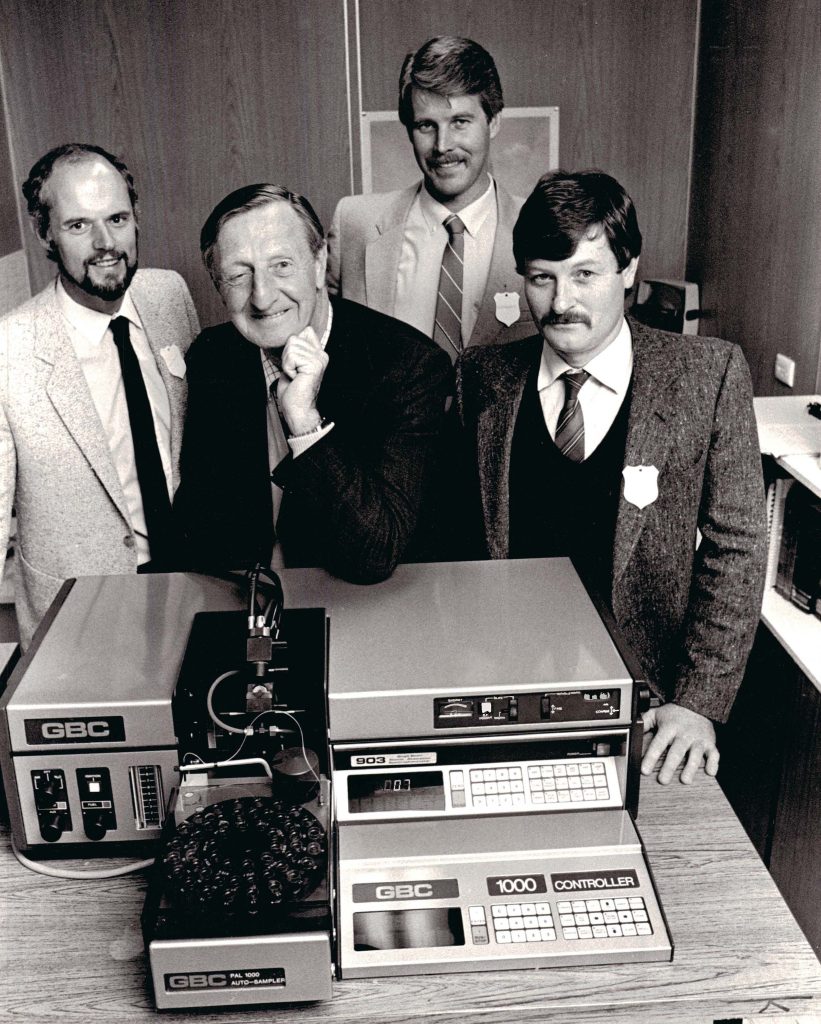

In this picture, Sir Alan Walsh (second from left) stands with GBC’s Directors from left, Peter Charlton, Clive Davenport and Ron Grey over an early GBC AAS – the 903 and System 1000.

High Quality Standard

English

English

Arabic

Arabic